From the fundamental understanding of your system, we can help you define your system requirements. We combine, analyze, and synthesize the information and specifications coming from various sources into comprehensive system requirements. Wether you have stringent specifications required by a client, or a definition coming from an operability group, or a baseline definition of a system, we use all the information available to ensure that the system requirements will meet the performance and safety criteria required.

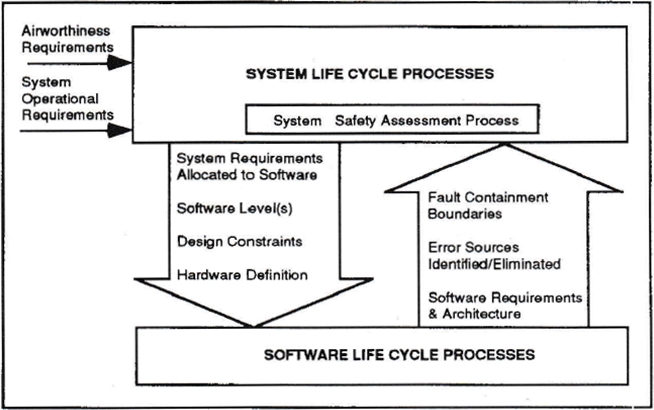

DO-178B

The following is a typical example of a fuel metering unit system requirements.

| R123567 | CSRD 2.3.4:FCU Torque Motor | Allocation : FCU Equip. Spec. |

| The FCU shall throtle the fuel flow using a torque motor. | ||

| R123568 | CSRD 2.3.4:FCU Torque Motor | Allocation : FCU Equip. Spec. + System Model |

| The FCU Torque Motor current to Torque shall be implemented as per the following curve. | ||

| R123569 | CSRD 2.3.4:FCU Torque Motor | Allocation : FCU Equip. Spec. |

| The FCU shall have a return spring conteracting the torque motor. | ||

| R123570 | CSRD 2.3.4:FCU Torque Motor | Allocation : FCU Equip. Spec. + System Model |

| The Torque motor return spring displacement to spring force is as per the following equation. | ||

| R123571 | CSRD 2.3.4:FCU Torque Motor | Allocation : System Model |

| The Torque motor dynamic characteristics shall be defined as per the following parameters : Tf:Torque Motor friction Coefficient Td:Torque Motor Damping Coefficient Ti:Torque Motor Inertia Tl:Torque Lever Arm Length | ||

| R123572 | CSRD 2.3.4:FCU Torque Motor | Allocation : Application Software |

| The FCU Torque Motor Current shall be commanded such as to provide closed loop control on the fuel flow. | ||

| R123573 | CSRD 2.3.4:FCU Torque Motor | Allocation : Application Software + System Model |

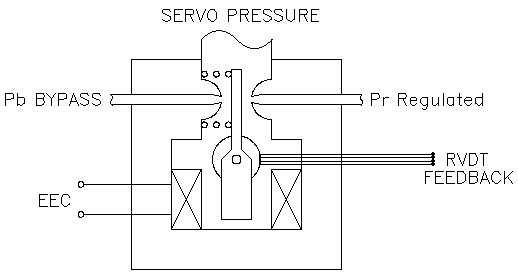

| The fuel flow shall be computed from the following equation : wfcalc=kf*(Pr-Pb)*f(RVDT FEEDBACK)*g(FUEL TEMPERATURE) where: kf : flow coefficient 0.234 Pr : Regulated Pressure 900 psi Pb : ByPass Pressure 120 psi f(RVDT FEEDBACK) : function of RVDT FEEDBACK g(FUEL TEMPERATURE) : function of FUEL TEMPERATURE | ||

| R123574 | CSRD 2.3.5:FCU RVDT | Allocation : Application Software |

| The FCU RVDT mV input to FEEDBACK position shall be implemented as per the following curve. | ||

| R123575 | CSRD 2.3.6:FCU FUEL TEMPERATURE | Allocation : Application Software + System Model |

| The FCU Fuel Temperature coeffient shall be implemented as per the following equation.

g(FUEL TEMPERATURE) = ... |

||

| R123576 | CSRD 2.4.5:FCU DYNAMIC PERFORMANCE | Allocation : Application Software |

| The Open Loop Gain Margin of the EEC+FCU combination shall be greater than 6 dB. | ||

| R123577 | CSRD 2.4.5:FCU DYNAMIC PERFORMANCE | Allocation : Application Software |

| The Open Loop Phase Margin of the EEC+FCU combination shall be greater than 45°. | ||

| R123578 | CSRD 2.4.5:FCU DYNAMIC PERFORMANCE | Allocation : Application Software |

| The Closed Loop Bandwidth of the EEC+FCU combination shall be greater than 20 rad/sec. | ||

| R123579 | CSRD 2.4.7:FCU FAULT DETECTION | Allocation : Application Software |

| The FCU shall detect a FCU Tracking Error Fault when the FCU Position Error exceeds 10 degreeg for more than 5 sec. | ||

| R123580 | CSRD 2.4.8:FCU FAULT ACCOMODATION | Allocation : Application Software |

| The FCU shall accomodate a FCU Tracking Error Fault by setting the FCU Torque Motor Current to 0.0 mA. | ||